The chain itself can come in many different forms, but there are two major categories: roller chain and silent-- or inverted tooth-- chain. I can't speak much about the silent chain, but it seems that they're not as hardy as the roller chain variety, nor as cheap and readily available. Furthermore, chain-guide.com claims that the silent chains are not suited to reverse drive, which is more or less what happens with regenerative braking. Therefore, I think classic roller chain is best suited to the task.

There are a number of criteria for choosing a chain and sprockets.

In real short form (click for my more in-depth explanation):

1) Gear ration should never exceed 7.

2) Sprocket center distance should be between 30 times and 50 times chain pitch. In no case should it ever exceed 80 times.

3) Try to choose sprockets with an even number of teeth.

4) Design the sprockets to have 110 teeth or less.

5) Design chain length to have an even number of links.

6) The optimum chain speed is around 12.5m/s.

7) Chain length is given by 2*Cm+(N1+N2)/2 +(N2-N1)^2/(4*pi^2*Cm), where Cm=C/p, N1 is the number of teeth on the first sprocket, N2 the # on the second, C is the center length, and p the chain pitch.

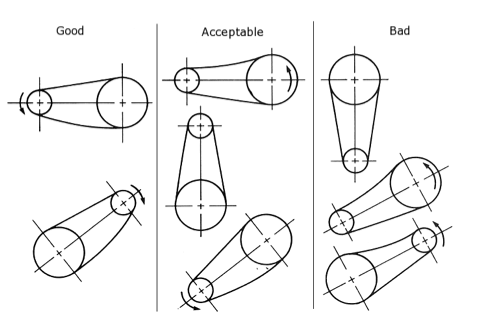

Chains should only be installed in a certain positions, as you can see in the following image. Also note that it's better to have the smaller pinion driving the larger one.

It should go without saying that you want the sprockets to be parallel and on the same plane. While chains still work when twisted a bit-- as on a bicyle, efficiency and longevity start suffering greatly so keep your sprockets lined up at all costs.